Growing & Processing Tobacco

The process of cultivating and processing tobacco into a cigar is a complex and labor-intensive procedure. In the following, we will take a closer look at this process so that you can better appreciate and enjoy the natural product that is a cigar.

As mentioned earlier, this description focuses on cigar tobacco, although some points can also be applied to the production of cigarette and pipe tobacco.

The Tobacco Plant

The scientific name of the tobacco plant is "Nicotiana tabacum," and it belongs to the nightshade family (Solanaceae). This genus also includes potatoes, tomatoes, peppers, eggplants, and other crops.

The name "Nicotiana" comes from the French diplomat Jean Nicot de Villemain, who around 1560 brought the tobacco plant from Lisbon to the French court and played a significant role in the spread of tobacco. He became the namesake of the genus and its primary alkaloid component, nicotine. Nightshade plants are easy to crossbreed by removing the male part of the flower and pollinating it with foreign pollen. The results can already be observed after a few weeks. However, the tobacco plant reaches full maturity only after a year.

The key characteristic of the Nicotiana genus is its alkaloid content, especially nicotine in the tobacco plant. Nicotine is synthesized in the roots and transported to the leaves, where it acts as an insect deterrent. The plant can reach a height of two to three meters and a weight of up to two kilograms. The inflorescences are multi-branched panicles with funnel-shaped flowers, red in Nicotiana tabacum and yellow in Nicotiana rustica.

The flower of the tobacco plant is cut early ("topped") before the first inflorescence develops. Otherwise, the plant's metabolism would focus on the flower, depriving the leaves of valuable substances.

The tobacco plant requires a minimum temperature of 15°C to grow. Cold is fatal for it: at 0°C, the leaves are damaged, and at temperatures below -3°C, the plant dies. Besides warmth, the plant also needs sufficient moisture but not too much watering, as excessive water reduces the "honey" in the leaves. These climatic conditions, however, also provide an ideal environment for common tobacco diseases. Mild winds can prevent fungal infestations, but strong winds and hail destroy the leaves, making them unsuitable for processing.

The Leaves of the Tobacco Plant

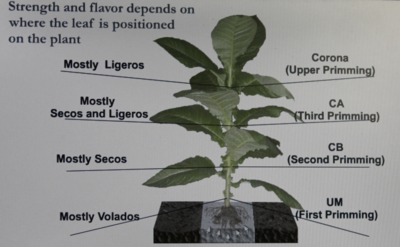

A tobacco plant is typically divided into six tiers, from bottom to top:

- libre de pie (foot)

- uno y medio (one and a half)

- centro ligero (light middle)

- centro fino (fine middle)

- centro gordo (thick middle)

- corona (top)

The leaves can also be categorized into three classes based on size, color, and texture:

Volado Leaves

The leaves from the lower part of the plant are called Volado. Receiving the most shade, they are the mildest tobacco leaves and are mainly used for the filler. The strongest and best leaves of this type are also selected as binder leaves.

Seco Leaves

The leaves from the middle part of the plant are known as Seco. These leaves are considered aromatic and have moderate strength.

Ligero Leaves

The topmost part of the plant produces Ligero leaves. Being most exposed to sunlight, they acquire a distinctive sweetness and are the strongest, most robust leaves of the plant.

Tobacco Varieties

Since around 1940, the foundation of all approved seeds in Cuba has been the Criollo. Shortly thereafter, an improved version called Corojo was developed. This variety is mainly used in Cuba for wrapper leaf cultivation. Based on these plants and seeds, the Piloto Cubano variety is cultivated, mainly in the Dominican Republic and Central America. Olor Dominicana is the native tobacco of the Dominican Republic, and another variety is San Vicente – a hybrid of the Piloto Cubano seed. See also: Piloto Cubano Tobacco.

Other varieties include Olor Carbonell and additional wrapper leaf varieties like Havana Vuelta Arriba, El Negrito from the San Vicente seed, Corojo 2006, and the successor of Piloto Cubano, Criollo 98.

In Nicaragua and Honduras, hybrid varieties like Habana92 and Habana 2000, along with Criollo for fillers and binders, as well as Connecticut tobacco for wrappers, are grown. The only indigenous variety in Honduras is Copaneco.

Other notable types include Sumatra (light) and Brazilian (dark) tobaccos, which are most commonly used as wrapper leaves. Hence the terms Sumatra and Brazilian cigars (light and dark cigars). These tobaccos are mainly used for short-filler cigars.

Tobacco – From Sowing to Harvest

One gram of tobacco seeds contains about 10,000 seeds. A tobacco plant produces between 5 and 20 grams of seeds. The seeds are usually sown in protected beds to prevent them from being washed away. About 800 seedlings or saplings are planted per square meter. Once the seeds are sown, they are covered with cloth or straw to protect them from the sun.

After about six to eight weeks, the seedlings are transplanted to open fields. Around 20 days later, soil is piled around the plant's base to promote the development of strong roots. Once the plant reaches a certain height, the flower is "topped," encouraging accelerated growth.

The entire work cycle, from transplanting to harvest, takes about four months. Tobacco growers (known as vegueros in Cuba) work from June/July to the following March, tending to different fields at different times. The soil is prepared between June and August. From September to early November, seedlings are raised in nurseries. From late October to late December, the plants grow, and from December to March, the leaves are harvested.

Tobacco Cultivation: From Sowing to Harvest

There are two primary methods of tobacco cultivation:

- With Tapados: Plants intended for wrapper leaf cultivation are covered with mesh screens (known as tapados or tela tapados) 10 to 20 days after transplanting. These tapados protect the plants from sunlight while retaining warmth, ensuring that the leaves do not become too oily, remain smooth, and grow larger.

- Without Tapados: Plants are grown under direct sunlight. These leaves are mainly used for filler and binder purposes. This method of ripening also allows for the development of various flavor profiles.

The cultivation of tobacco can generally be divided into three steps:

- Sowing

- Harvesting

- Processing

-

Sowing the Seeds

Tobacco cultivation begins with sowing: one gram of tobacco seeds contains about 10,000 seeds. A tobacco plant produces between 5 and 20 grams of seeds. The seeds are usually sown in protected beds to prevent them from being washed away. About 800 seedlings or saplings are planted per square meter. Once the seeds are sown, they are covered with cloth or straw to protect them from the sun.

After about six to eight weeks, the seedlings are transplanted to open fields. Around 20 days later, soil is piled around the plant's base to promote the development of strong roots. Once the plant reaches a certain height, the flower is "topped," encouraging accelerated growth.

The entire work cycle, from transplanting to harvest, takes about four months. Tobacco growers (known as vegueros in Cuba) work from June/July to the following March, tending to different fields at different times. The soil is prepared between June and August. From September to early November, seedlings are raised in nurseries. From late October to late December, the plants grow, and from December to March, the leaves are harvested.

-

Harvesting the Tobacco

Careful harvesting at the right time is crucial for the subsequent blending of tobaccos. Cigar tobaccos should be harvested in a pre-ripe state, while they are still green and just beginning to lighten in color. This helps keep the sugar and starch content of the leaves low, as these increase significantly as the leaves turn yellow during ripening. Once the leaves begin to die, they lose the ability to process sugars and starch.

Harvesting is usually done in the morning to make the leaves easier to pick. In Cuba, harvesting is done by hand (picking), and the leaves are plucked individually from bottom to top based on their ripeness. This method ensures an accurate count of the leaves and provides precise knowledge of the yield.

In other countries, such as Nicaragua, the priming method is used, where three to four leaves from a tier are harvested simultaneously. In Mata Fina, Brazil, entire plants are cut with the stem and dried, ensuring continued nutrient supply. In the U.S., mechanical harvesting is also common due to larger fields.

-

Processing the Tobacco

After harvesting, the leaves are slowly and carefully air-dried. The leaves are completely exposed to local conditions. In curing barns, temperature and humidity are regulated by opening and closing doors at both ends to maintain balance. This process takes about 25 days.

Next, the leaves undergo the first fermentation. This fermentation reduces impurities such as acids, tar, and nicotine while releasing a rich array of aromas. This step takes approximately 45 to 60 days. After the first fermentation, the leaves are selected and sorted based on size, color, and texture.

Next, the leaves are handed over to despolilladores (leaf strippers), who remove the stems, re-sort the leaves, and make the final decision about their suitability for further processing.

This second fermentation takes 45 to 60 days, depending on the leaf type: 60 days for Ligero, 45 days for Seco and Volado, and 35–40 days for wrapper leaves. The leaves are moistened with water and covered with burlap. Finally, the leaves are packed into rectangular bales wrapped in palm bark or jute and sent to factories or warehouses for additional aging and maturing over several years.