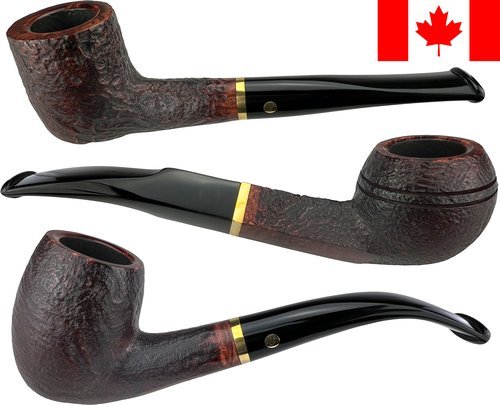

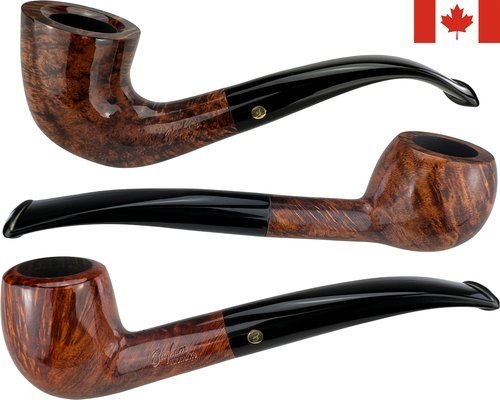

Brigham: Bestseller

Brigham: All items

Brigham Pipes: Tradition and Innovation Since 1906

Roy Brigham founded a pipe repair workshop in Toronto in 1906 after completing his apprenticeship with an Austrian pipe maker. By 1918, the business had grown to include five additional craftsmen, proving its economic success. Having seen and repaired many pipes and models, Roy Brigham became well aware of the weaknesses in pipe construction. At the same time, he noticed that many pipe smokers complained about tongue bite, a challenge that would occupy his attention for years to come.

Roy Brigham and the Revolution of Pipe Filters

Soon, the company began producing pipes that were better constructed and of higher quality than what was commonly available on the market. In 1938, Roy’s son Herb joined the company, and together they conducted experiments on tongue bite. They discovered that pipe filters could significantly reduce this issue.

They then developed filters using various domestic and imported materials. However, only filters made from bamboo and “rock maple” – also known as sugar maple – proved effective. Since bamboo was difficult to obtain and relatively expensive, they decided to use the locally available maple wood for future production.

Small Masterpieces of Maple Wood: Brigham Rock Maple Filters

The Brigham Rock Maple Distillators Filters are made of a maple wood tube with an aluminum tip. The filter is about 9 cm long and fits almost equally into the shank and mouthpiece. Its filtering performance is excellent, especially in smoothing the smoke and absorbing moisture. Unlike the commonly used filters in Europe, the manufacturer explicitly recommends the reuse of these filters. They can even be rinsed with water and dried afterward. However, the filter’s effectiveness decreases over time. After 20 to 30 uses, it should be replaced.

Eco-Friendly Alternative

Since the pipe filters are primarily made of local maple wood and designed for multiple uses, this filter system is not a disposable product.

Waste is avoided. Unlike activated carbon filters, no fossil materials are used. Additionally, there is no mining or extraction process as with meerschaum filters. The raw material grows right outside the doorstep in Toronto.

Brigham Pipes: Canadian Craftsmanship with History

The golden era of Brigham pipes was the 1960s when more than 40 employees worked in production. However, due to a steadily increasing shortage of skilled workers, worsened by an aging workforce, most of the production had to be relocated to the European Union in 2001, where it still takes place today.