Hecho a Mano - Partially Handcrafted Cigars

The term "hecho a mano" means handmade, but especially in the case of Cuban cigars, this label typically refers to cigars that are partially machine-made. Completely handmade cigars are labeled totalmente a mano.

In other cigar-producing countries like Nicaragua, Honduras, Costa Rica, or the Dominican Republic, the term "Hecho a mano" or "Totalmente a mano" is used for cigars that are completely handmade.

The difference between a fully handmade and a partially machine-made cigar lies in the filler. For cigars labeled "hecho a mano," the filler is made by machine. Only then is the filler wrapped with a wrapper leaf by hand, and the cap is closed manually.

The method of production is indicated on the bottom of the cigar box. "Hecho en Cuba" appears on all boxes from Cuba; if it appears alone on the box, it indicates that the cigars are machine-made. Boxes containing machine-made cigars also carry a stamp with the word "Mecanizado." "Hecho a mano" means that the cigars are partially machine-made, while "Totalmente a mano" indicates the completely handmade production of cigars.

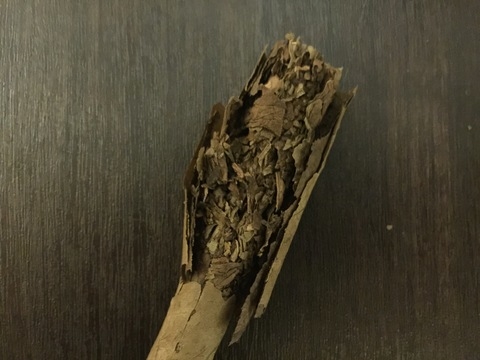

Interior of a Cigar

A cigar consists of three components: the filler (tripa), the binder (capote), and the wrapper (capa). The filler, also called the "roll," consists of the filler tobacco wrapped in the binder. This roll is then wrapped with a wrapper. These leaves, especially in handmade cigars, are of high quality.

Three Methods of Cigar Production

The best method is, of course, handmade production – totalmente a mano – tripa larga. This refers to the use of long filler leaves, and it requires many years of experience from the roller to create well-made cigars. The second method is "tripa corta." Here, scraps from the long filler leaves, which are left over when the cigars are cut, are mixed with other selected and cut leaves. The wrapper is applied by hand. The third method is machine-made production. In fully machine-made cigars, the filler mixtures are fed into machines to form rods and are wrapped with an endless binder. A tube is created, which is closed at both ends. The wrapper is then applied, and the cigars are cut to the proper length by machine. In the partially machine-made process, used for cigars of somewhat higher quality, an employee manually places the filler mixture into a chute. The binder leaves are also manually placed on a plate and then cut. The leaves are then placed overlapping onto a conveyor belt, which carries them into the wrapping machine. The wrapper is then applied by hand again.

Qualitative Differences

For a handmade cigar, a blend of long leaves is necessary, which must be of high quality and have matured for a longer time. Additionally, it takes many years of experience for the torcedores (rollers) to shape these leaves into a good cigar. Machine-made cigars typically contain cut tobacco (small chopped tobacco leaves), also known as picaduro, as the filler. The aficionado will likely prefer one of the handmade cigars. However, machine-made or partially machine-made cigars can also have good quality and can be a good alternative, often at a lower price. In the end, besides a reasonable price-performance ratio, the aficionado’s taste is the deciding factor.

Further topics

Discover & enjoy

In our shop you will find: